By Erica Baker

First impressions are extremely important, especially for any company that wants to grow its business. When you walk into a public restroom that has an unpleasant smell, it’s likely that you’ll immediately turn around and walk out. When a restroom has an odor, 47% of people say an unclean restroom shows that a company doesn’t care about its customers (Bradley Corp. Survey).

So how does a company prevent this poor first impression from happening? The first (and obvious) thing to do is to regularly clean your restroom and the second is to make sure that it consistently smells good. There are a variety of odor-control solutions available to use such as urinal screens, active air fresheners, passive air fresheners, urinal/commode mats, and more. Read below to learn more about the different types of odor control solutions that can help keep your restrooms smelling fresh.

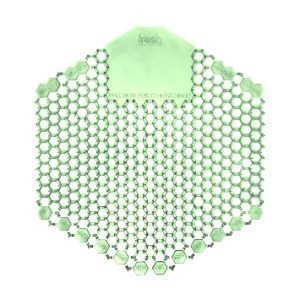

It’s a good idea to use a fragrant urinal screen, such as the Wave 3D, for the dual purpose of cleaner restrooms through splash prevention and better smelling restrooms. Urine splash is inevitable so it’s important to minimize it as much as possible when it tracks, it is unsanitary and the uric acid damages floors seep into grout and cracks causing reoccurring odors.

Having an air freshener on the wall in the restroom is great, but it doesn’t always address odors in the stalls where the unpleasant smells are coming from. Using an air freshener that clips directly onto the toilet, such as the Eco Bowl Clip, can more effectively eliminate odors.

Right after the restroom is cleaned, it smells great, but sometimes the odors around toilets and urinals, return and linger. That smell is usually urine that has seeped into the floor where typical cleaners can’t reach. Using a multi-purpose cleaner and deodorizer concentrate that contains bio-actives that break down complex compounds (the cause of odors), such as Bio-Conqueror 105, to penetrate deep into spaces to remove stubborn odors is a great solution.

Erica Baker

Marketing Coordinator • Fresh Products, LLC

Erica Baker is an experienced Marketing Coordinator with a demonstrated history of working in the medical device industry. Skilled in B2B Marketing, Social Media Marketing, Email Marketing, Print, and Microsoft Office Suite. Strong marketing professional with a Bachelor of Science, focused in Marketing from Bowling Green State University.

Amy W. Richardson

Amy W. Richardson